Industrial floors for the rubber and plastics industries

Rubber and Plastics

WHEN KNOW-HOW IS NEEDED, RECODI KNOWS HOW! Italian rubber and plastics manufacturers have reached a level of innovation that places them at the top of the global market. Accordingly, they are looking for highly skilled partners to work with them on the design and construction of their plants. Recodi, a company committed to delivering high-quality solutions through research and technological innovation, delivers cutting-edge solutions designed to meet the requirements of the manufacturing facilities in this sector.

Starting with their floors, these companies – which are constantly subject to inspections by certifying bodies and visits by clients – require well-organized, easy-to-clean production areas that are able to communicate at first glance the quality of the business and of its products.

The experience and expertise accumulated by Recodi in the rubber and plastics industry over many years allows us to lay floors designed to deal with common problems in this sector: the rubber being manufactured often sticks to the floor, and so having a smooth (self-levelling coating) facilitates the cleaning operations.

In the production of rubber mixtures, for example, the substantial use of carbon black – a very fine black material that settles everywhere – makes it advisable to create divisions between the production area and the offices, and to select floor colours that are not too light.

The use of floor markings, or the alternation of zones of different colours, is very useful in allowing better visibility and recognition of the various working areas, with the transit areas clearly delineated.

In the gasket washing and tumble-finishing areas, the presence of water on the floor and the tendency to drag containers full of products make it essential to have a thick, waterproof floor that is resistant to mechanical aggression.

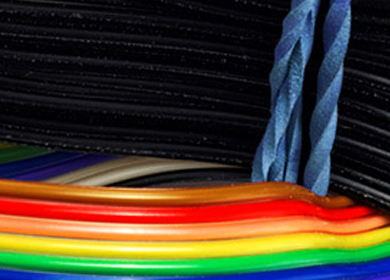

In the manufacture of cables, which are wrapped around wooden reels and rolled across the goods-handling areas, it is important that the floor is flat and jointless. During the process of inserting the copper core, the cables are processed using nitrogen at a temperature as low as -20°C, and so in the vicinity of the processing operations is it crucial to have a floor that is resistant to thermal shocks.

With 50 years of consolidated experience and a constant sensitivity towards the latest research and technological innovation, Recodi is the ideal partner for rubber and plastics manufacturers thanks to our ability to design and install resin floors that are resistant, durable, hygienic and functional, with specific logistical and safety features to meet the requirements of these working environments.