Industrial floors for the chemical/pharmaceutical and cosmetics sectors

Chemical-Pharmaceutical and cosmetics

Health and beauty do not come out of nowhere. In the chemical/pharmaceutical and cosmetics industries, results and products are the fruits of a painstaking process that is monitored all the way along the production chain. In the same way, a knowledge of the specific requirements of flooring for these sectors does not come about by chance. Over the course of its 50 years in business, Recodi has built up a wealth of specialist expertise based on respect for the indispensable characteristics of the project and for the current regulatory framework: maximum hygiene, easy of cleaning and sanitization, and high levels of chemical/physical resistance.

We are acutely aware of the importance of the safety standards, which must be constantly applied and compliant with the regulations, to avoid the product coming into contact with sources potentially contaminated by dirt.

In addition, Recodi floors have an extremely appealing look that helps to transmit an image of quality to all visitors, clients and certifying bodies. Through our numerous experiences in chemical/pharmaceutical and cosmetics companies, we have laid floors in all of the different areas (not just the manufacturing zones), evaluating in each case the specific requirements and designing the most appropriate solutions:

- packaging lines

- mixing rooms

- laboratories

- production areas

- white rooms

- entrances

- research areas

- corridors

- equipment rooms

- CIP (cleaning in place) areas

- controlled-atmosphere areas

- research laboratories

- quality-control laboratories

- changing rooms.

Some of the recurring requirements, which have led us to develop technologies and applications that have now been widely tested, include:

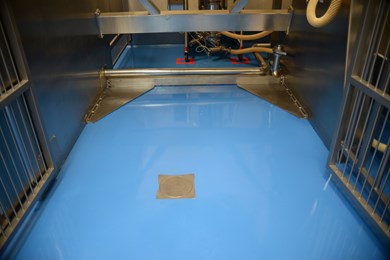

Hygiene and presence of water

The high standards that meet the industry regulations – which are in place to ensure that the product does not become contaminated – require the use of waterproof, jointless coatings that are easy to sanitize. It is important to use skirting strips to stop bacterial proliferation in corners and at the points where the floor meets the walls. In the areas where washing operations are carried out, the floor-level drainage wells and channels must be properly treated during the laying of the resin floor to avoid infiltration of water into the foundations, which can result in the detachment of the coating.

Non-slip

The presence of liquids at floor level (water, oil, silicone in the processing areas and of water and detergents in the washing areas) requires non-slip surfaces that are able to maximize the worker and vehicle safety.

Chemical aggression

The chemical substances used in manufacturing operations may spill onto the floors and corrode them, if the floors are not properly protected. It is, then, important to select an adequate resin coating.

Mechanical resistance

Given the frequent use of very heavy stainless-steel equipment, composed of many ports that must be assembled, re-assembled, moved around and washing during their working lives operations, and which can accidentally fall to the ground, it is essential to install floors that can resist impact and weight. The handling of goods and equipment is a critical factor in relation to weight, both in terms of the type of equipment being used (fork-lift trucks with steel wheels), and in terms of the constant repetition of the movements.

Anti-static finishes

Many processes involve the use of highly flammable products and the rooms where these processes are carried out are often subject to Atex directives, according to which the floors must comply with regulations on electrical resistance.

High-quality image

Pharmaceutical companies often undergo inspections by monitoring and certifying bodies. For this reason, it is essential to lay a floor that contributes to creating an image of quality, professionalism and organization. To this end, it is crucial – particularly in the production and warehousing areas – to use floor markings that helps to delineate the various working areas. Pharmaceutical companies are subject to frequent re-vamping operations to modify the production set-up, and require floor overhauls to be completed to very tight deadlines; it is, therefore, important to offer solutions that can be rapidly implemented and subsequently removed.